Inexpensive Lift Repair Near Me: Expert Technicians at Your Solution

Inexpensive Lift Repair Near Me: Expert Technicians at Your Solution

Blog Article

Digging Into the Globe of Lifts: Typical Problems Encountered by Different Lift Mechanisms

As we browse through the vertical transportation systems of modern-day structures, elevators stand out as an important part of our day-to-day lives. From hydraulic elevators to grip systems and machine-room-less designs, each lift type comes with its collection of typical concerns.

Hydraulic Lifts

Hydraulic elevators, often chosen for low-rise buildings, use fluid pressure to control the motion of the lift automobile (lift repair companies). This mechanism involves a hydraulic pump pushing oil into a cyndrical tube, causing the lift to relocate the desired instructions. While hydraulic lifts are understood for their smooth and peaceful procedure, they do include their own collection of typical problems

One widespread issue with hydraulic lifts is oil leakage. Furthermore, issues with the control system, such as faulty valves or a malfunctioning pump, can trigger disturbances in the elevator's movement.

Regular maintenance and punctual fixings are necessary to guarantee the smooth performance of hydraulic elevators. By addressing these common concerns proactively, structure proprietors can lessen downtime and guarantee the safety and efficiency of their vertical transportation system.

Traction Elevators

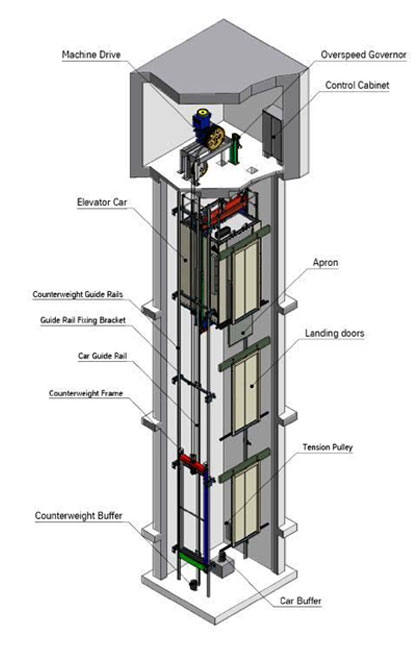

When taking into consideration upright transportation systems in structures, one more usual kind aside from hydraulic lifts is the grip lift. Traction elevators operate making use of a system of ropes and counterweights that relocate the elevator vehicle by grasping onto the hoist ropes. This mechanism enables smoother and much faster vertical transportation compared to hydraulic systems.

Among the usual problems dealt with by traction lifts is rope wear. The constant movement of the ropes within the grip system can lead to deterioration gradually, possibly causing the lift to breakdown or become dangerous for usage. Normal inspections and upkeep of the ropes are important to guarantee the elevator's appropriate performance and safety.

An additional problem that traction elevators might encounter is related to the control system. Problems with the control system can bring about concerns such as unpredictable movement, hold-ups in response times, or perhaps full closures. Routine testing and upkeep of the control system are vital to protect against such concerns and make sure the elevator's dependability.

Machine-Room-Less (MRL) Elevators

One of the essential elements of MRL elevators is the small gearless grip equipment that is installed within the hoistway. This maker successfully drives the lift automobile without the demand for bulky devices discovered in traditional traction elevators. Additionally, MRL lifts generally make use of a counterweight system to stabilize the automobile, more boosting their power effectiveness.

Despite their advantages, MRL elevators might encounter challenges connected to repair and maintenance because of the confined space for equipment setup. Availability for servicing elements within the shaft can be limited, needing specialized training for professionals. Appropriate maintenance schedules and normal inspections are vital to make certain the continued smooth procedure of MRL lifts.

Overloading and Weight Limit Issues

Straining and weight restriction concerns are essential concerns in lift procedures. Elevator makers layout raises with particular weight abilities to make certain passenger safety and security and devices longevity.

When elevators are lift companies in London strained, it places excessive pressure on the electric motor, cables, and various other components, possibly causing breakdowns or breakdowns. Safety and security devices such as sensing units and overload sensors are in area to avoid lifts from moving if they discover excess weight. Furthermore, exceeding weight limitations can lead to boosted energy usage and wear and tear on the lift system.

To mitigate overwhelming concerns, developing supervisors ought to plainly display weight limitations in elevators and inform occupants on the relevance of adhering to these constraints - lift repair companies. Routine maintenance checks by certified professionals can likewise aid make certain that elevators are running within risk-free weight parameters. By addressing overloading and weight limitation problems proactively, structure owners can improve elevator security and performance

Electrical System Failings

Surpassing weight restrictions in lifts can not just lead to mechanical concerns however likewise possibly contribute to electrical system failings within the lift framework. Electrical system failures are an important worry in elevator operation, as they can create unforeseen shutdowns, malfunctions, or also security risks.

Additionally, power surges or fluctuations in the electric supply can likewise disrupt the elevator's procedure, impacting its performance and safety. These electric disruptions can damage sensitive lift parts such as control board, circuit card, or sensors, bring about system failings. Routine maintenance and inspections are essential to identify and resolve possible electric problems immediately, guaranteeing the safe and efficient operation of lift systems. By adhering to weight limits and performing routine electric system checks, building proprietors can reduce the risk of electric failures in lifts.

Final Thought

Hydraulic elevators, usually preferred for low-rise structures, utilize fluid pressure to regulate the movement of the lift vehicle.When thinking about upright transport systems in buildings, an additional typical type apart from hydraulic lifts is the visit this website grip elevator. Traction elevators run making use of a system of ropes and weights that move the elevator car by grasping onto the hoist ropes. Unlike standard lifts that need a separate maker space to house the devices, MRL lifts incorporate most of the parts within the shaft, getting rid of the need for a specialized device space.In verdict, elevators deal with usual issues such as hydraulic breakdowns, traction system failures, and electric system problems.

Report this page